Orthopedics

Most of the anatomical models relate to fractures (e.g. pelvis or heel fractures and spine trauma) and bone cancer. 3D printed models made of interlocking parts can improve pathological structures visibility located in hardly accessible points. 3D printed models for traumatic injuries are commonly required with considerable urgency: relying on fast 3D printing technologies, we can provide them within 12 hours, depending on the bone district dimension. Our 3D models are also used to choose and test the most suitable surgical instruments and devices (metal bars, screws, plates etc.) for every single patient, or even design patient-specific instrumentation (templates, cutting guides etc.). The use of the 3D printed model in the preoperative phase reduces operating and anesthesiological times improving benefits for patient’s health and limiting hospital’s costs.

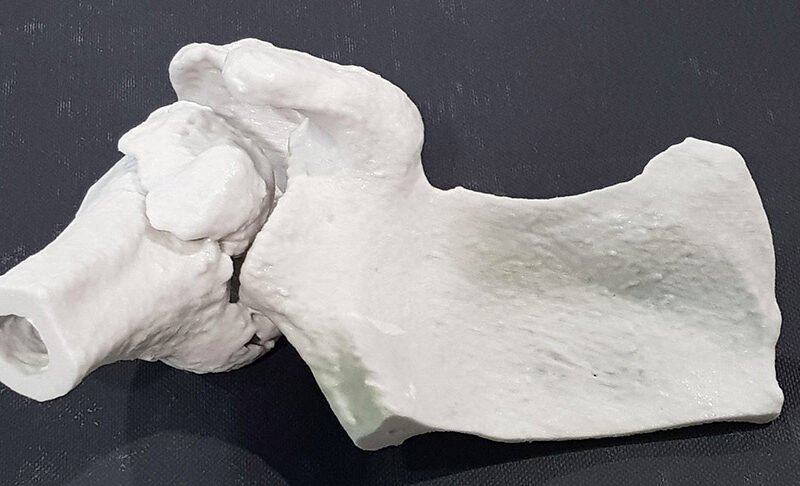

The patient-specific model represents a hemi-pelvis with a compound fracture. The model has been useful to evaluate the degree of the fracture, the bones to be reconstructed and the presence of bone fragments.

Traumatic orthopedic injuries, like the case taken into account, require great timeliness of realization. Thanks to the available technologies, we are able to deliver this kind of models within 24-48 hours from the radiologic images’ availability. The anatomical model is printed in plaster material having a consistency and mechanical response similar to the bone tissue.

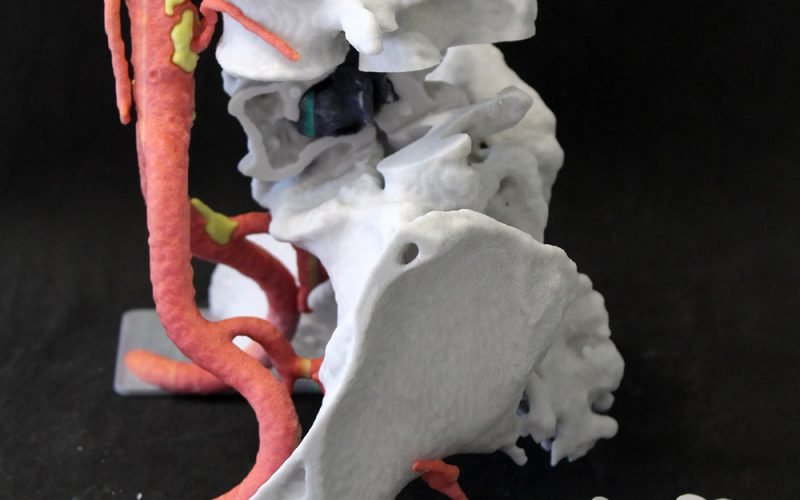

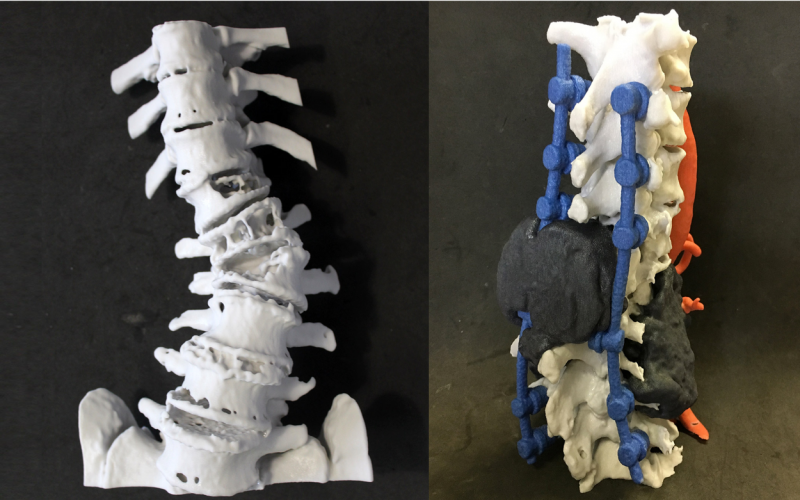

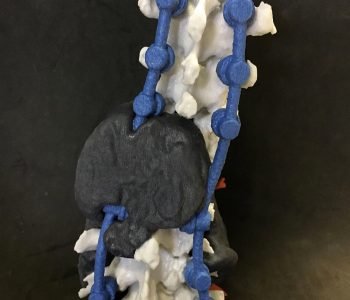

The first patient-specific model describes a spinal column with an evident scoliosis due to the presence of a tumor affecting the bone tissue. The 3D printed model has been useful to evaluate the pathological curvature of the spine and to plan the surgical treatment involving the modeling and the placement of metal bars to straighten the spinal column. The surgeon has been able to properly model and evaluate the location of the bars directly on the 3D printed model avoiding longtime surgery and reducing patient’s hospitalization and costs.

The second 3D printed model is related to a re-intervention on the same patient, due to the tumor recurrence. The tumor caused a worsening of the patient’s scoliosis and the surgeon asked for a 3D printed model to properly plan the spine cancer complex resection.

The model represents a case of left foot with multiple tarsal and metatarsal fractures. The model has been useful to evaluate fractures’ morphology and location and to properly plan surgical bones reconstruction. The model does not include the phalanges since they have not been involved in the surgery.