Otolaryngology & Maxillo-Facial Surgery

Temporal bone 3D printed models can be used by surgeons to properly plan the placement of hearing aids and prosthesis. Mandibular models are useful in surgical planning of both the demolishing and reconstructive phases that follow the removal of mandibular tumors. Our 3D models have also been used during the pre-operative phase for modelling metal plates for reconstruction, thus allowing a reduction of operating and anesthesiological times.

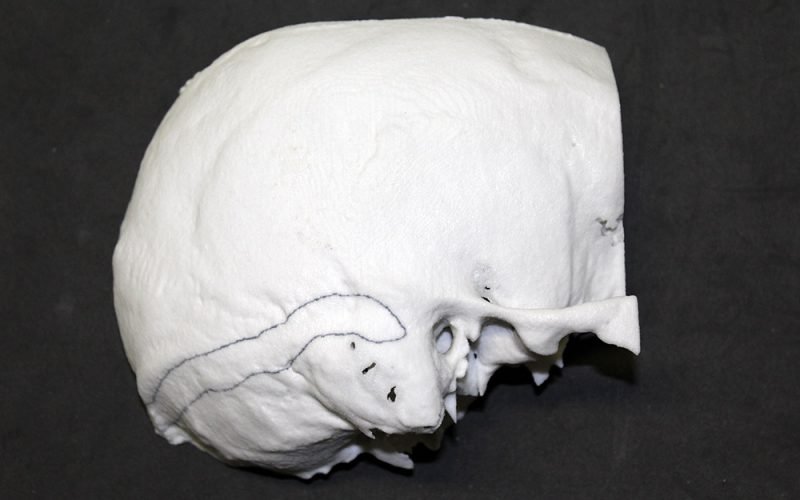

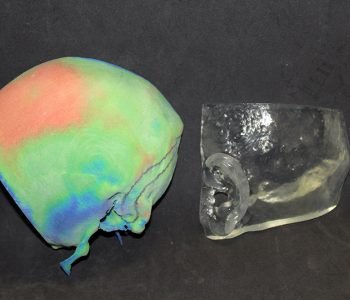

The 3D printed model has been used to properly plan the surgical placement of a transcutaneous bone conduction hearing device. The transducer can be grafted only where the temporal bone is adequately thick.

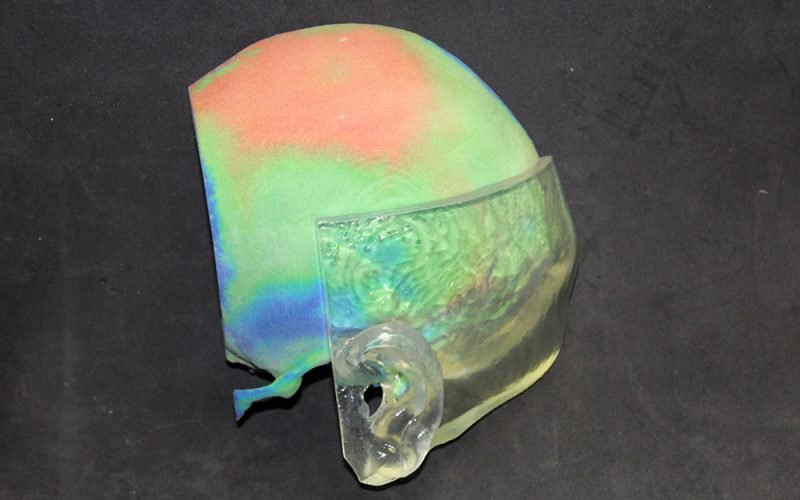

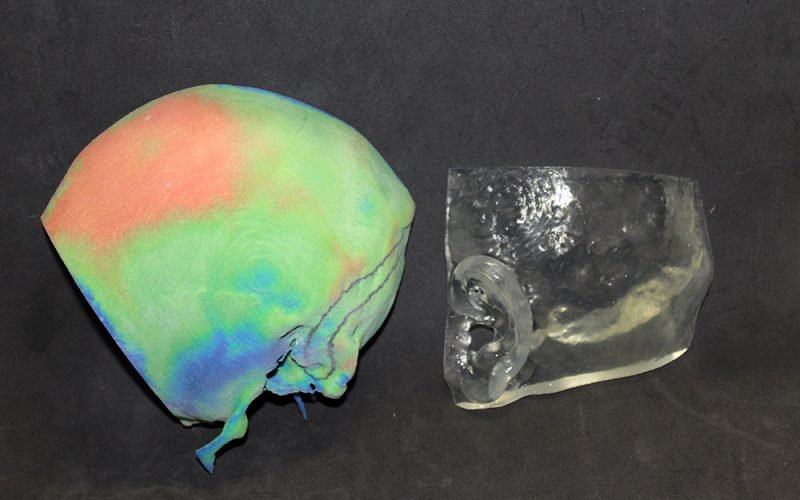

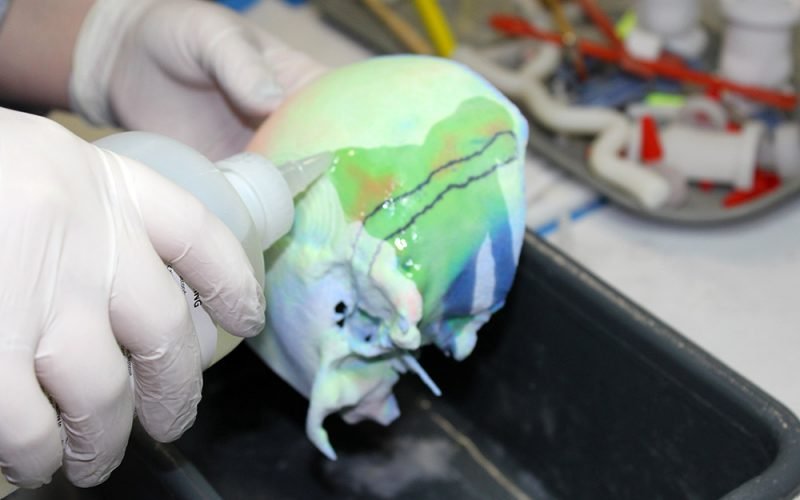

The model is made of three components: the reconstruction of the temporal bone printed in chalk powder with different colors representing the bone thickness (topographic thickness map), the reconstruction of the soft tissues above (skin) and a template both printed in transparent photopolymer resin. Transparency is fundamental to allow the surgeon to visualize the color map behind, in order to properly detect the most suitable location for the hearing device and to plan the surgical access.

In the operating room the template can be directly placed on the patient skin in order to find exactly the same access point identified on the model. Both the temporal bone and the soft tissues are reconstructed from MDCT images. The color thickness map is obtained through image processing techniques.

The patient-specific model has been useful for properly planning a jaw tumor resection and the related jawbone reconstruction. The model is a 3D reconstruction in chalk powder of the patient’s jaw undergoing a right emi-mandibulectomy. The model has been particularly useful for plaque modelling in jaw reconstruction procedure. Following this approach, the surgeon has been able to properly model the metal implant on the 3D printed model without shaping it directly on the patient, avoiding a longtime surgery, reducing hospitalization and costs.